Real-Time, On-Site Quality Control

Our systems scan and analyze as-built conditions immediately, in the field, for real-time quality control and corrections before changes are difficult to make.

Quality Control Services:

-

Compare concrete forms to a model before and after a pour.

-

Floor flatness/floor levelness (FF/FL) to ASTM E1155-20.

-

Identify peaks & valleys on a poured floor before and/or after curing.

-

Ensure elevator cores are built within tolerance.

-

Observe how a floor will drain and compare to the design.

-

Compare steel installation to a model.

-

Compare as-built stub & sleeve locations to design before a pour.

-

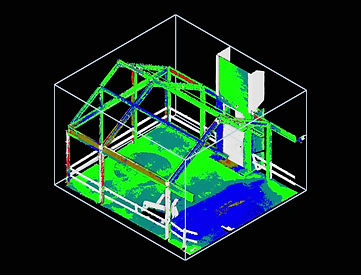

Compare MEP as-built to models for clash detection.

-

As-built to model inspection (2D and 3D).

Concrete forms are inspected for precise installation before the pour and then re-checked for post-pour movement. After stripping, the concrete is analyzed for as-built conditions.

Concrete floors are tested for flatness and levelness at any time during the pour so that changes can be made before the concrete hardens. Floor analysis can be done without a model or even a plan.

As-built elevator cores are compared to tolerance schedules. Here, the floor, right wall, and back wall look good. The left wall is starting to fall out of tolerance.

Erected steel is compared to the design during and after installation.

Floor profiles are verified to ensure proper draining. Floor analysis can be done without a model or even a plan.

Floor Drain

Stubs and sleeves are compared with a model (2D or 3D) to ensure that they are installed as designed before a pour.

Please

to discuss how we can help.